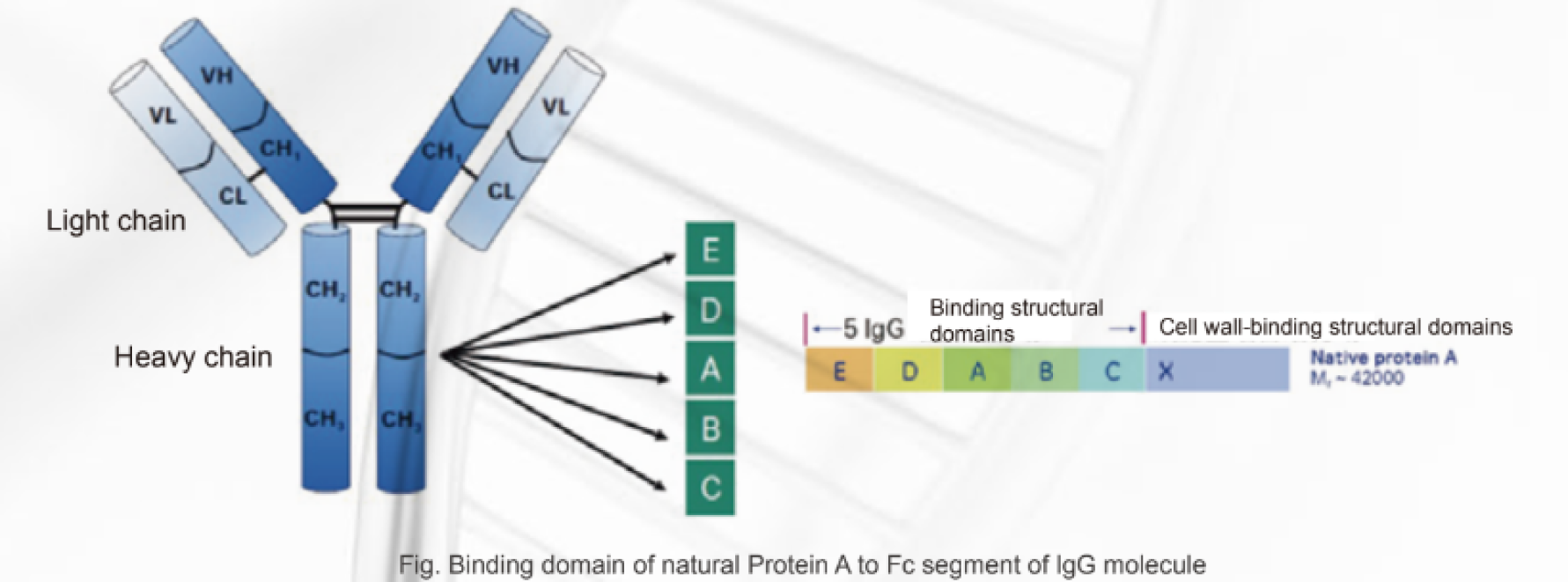

Affinity resins were established and developed based on the principle of specific adsorption between biomolecules and other ligand molecules to achieve purification of target molecules by specific adsorption between the ligands on the medium and the target molecules. Protein A is a staphylococcus cell wall protein with a molecular weight of 42 KD, which contains five Fc segments that bind specifically to the Fc segment of antibody IgG molecules. It contains five structural domains that bind specifically to the Fc segment of the antibody IgG molecule.

VDO has successfully developed arProtein A Focurose HR by linking its own modified Protein A ligand to cross-linked agarose. arProtein A Focurose HR is mainly used for the separation and purification of ascites, cell culture supernatants, serum-derived monoclonal antibodies, multiple antibodies and Fc-tagged proteins. The advantages of high loading capacity, stable alkaline resistance, excellent purification, good reproducibility, and direct substitution significantly reduce the customer's R&D and production costs.

High rigidity Agarose base holder

Particle size uniformity ~75μm

High alkali resistance 0.5M NaOH

Stable in all commonly used buffers

Anti-pressure low

Note: (1) The binding load of the resin will vary depending on the source and isotype of the

sample.

(2) Resins that are immersed in the eluent for a long time will lead to hydrolysis of the ligand and

eventually

affect the resin loading.

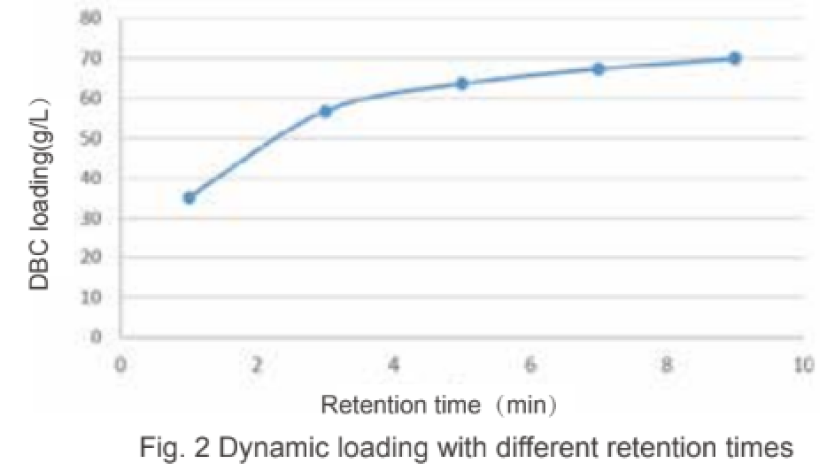

The average dynamic binding load > 60 mg/mL, and the recommended retention time was 5 min.

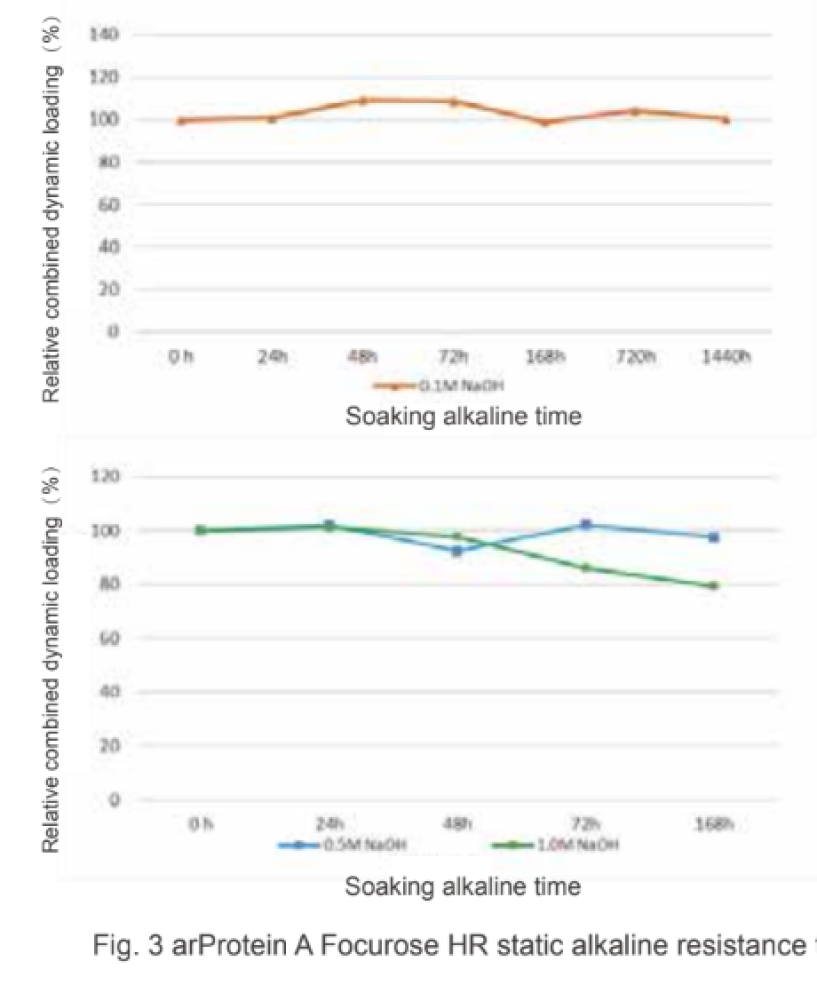

0.1M NaOH immersion for 1440h, DBC load was not affected; pressure resistance of 0.5 MPa for this resin. 0.5M NaOH, 1M NaOH immersion for 168h, DBC load decreased <20%.

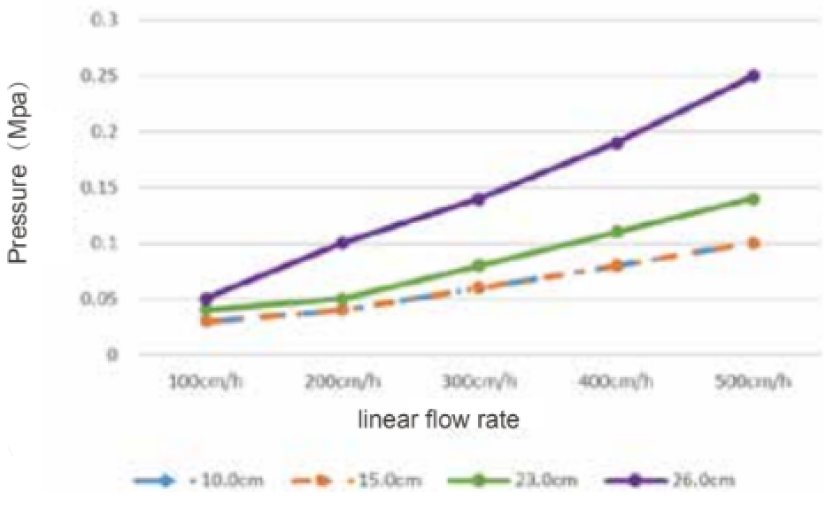

At the same column height and linear flow rate, the backpressure of our R&D type columns is comparable to that of production grade columns.

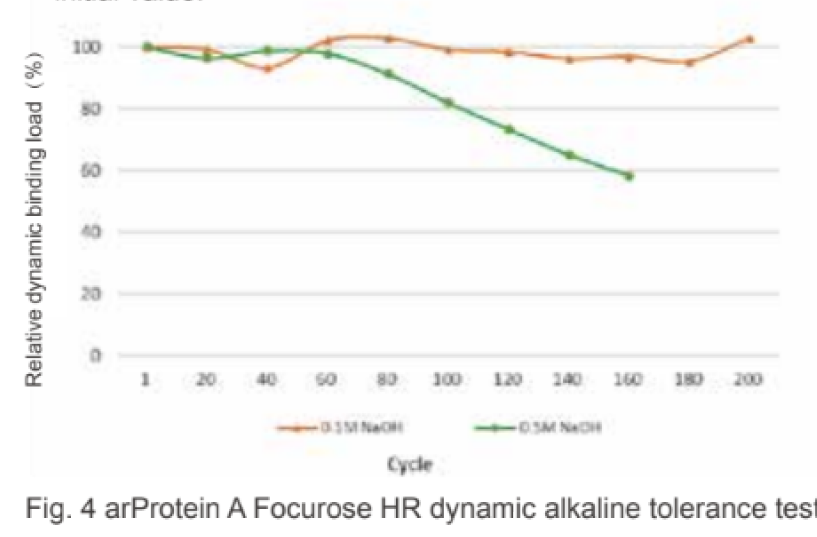

0.1M NaOH 200 cycles DBC remained essentially unchanged; 0.5M NaOH 100 cycles DBC was maintained at 80% of the initial value.

0.1M NaOH was used before and after the single experiment to disinfect for 15 min (equivalent to after 400 alkaline washes); The DBC loading was kept at about 60 mg/mL, and the percentage of decrease within 160 times within 15%.

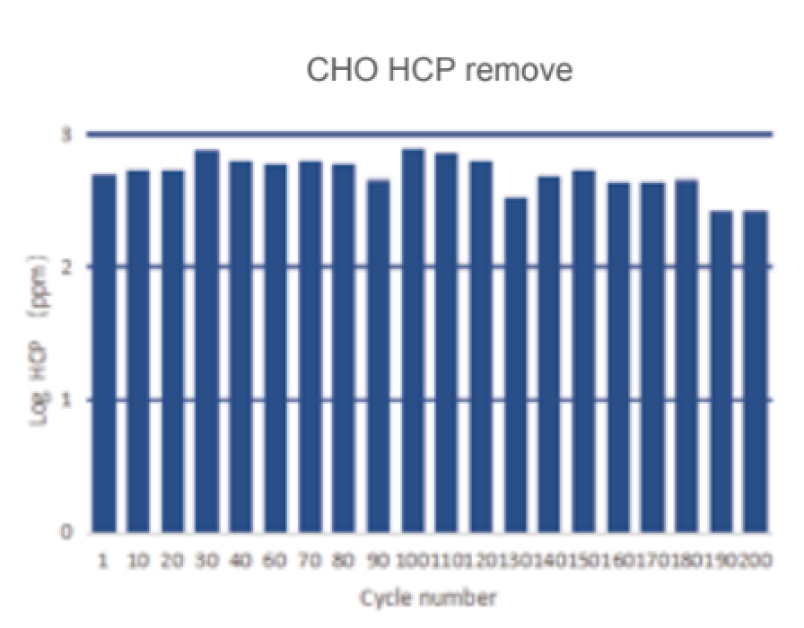

The HCP residues were all within 800 ppm in 200 times of single antibody life validation, which was consistent with imported resins.

The recovery rate was greater than 94%. The recovery rate did not decrease significantly over the lifetime of the 200 monoclonal antibodies, and was essentially within 10%.

The residue of Protein A ligand was less than 10 ppm in 200 times of monoclonal antibody lifetime validation, and there was no significant loss of ligand within 80 times of use.

The purity of SEC was maintained above 95% in 200 lifetime validations of the monoclonal antibodies, indicating that the filler is highly stable in terms of purity enhancement.

Please fill in the order form and we will contact you within 2 working days.